The history of American and European wood-burning culture

Wood burning has been a staple of American culture and history since colonial times, serving not just as a source of vital warmth and coziness, but also as a central feature reflecting style and romance.

The history of factory-built fireplaces is linked to the post-World War II housing boom and the search for cost-effective alternatives to masonry fireplaces. The development of these fireplaces was propelled by Underwriters Laboratory standard UL 127, which facilitated their installation with minimal clearance from combustibles. Despite initial issues with the standard, these fireplaces became incredibly popular due to their affordability and ease of installation, revolutionizing fireplace installation in both single and multi-family homes.

Woodstoves, with a history extending back to Europe and receiving American innovation from Benjamin Franklin, surged in popularity during the late 1970s when oil and gas prices soared. This resurgence in wood as a renewable energy source led to rapid advancements in stove design, balancing energy efficiency with aesthetic appeal. Following the energy crisis, environmental concerns brought about strict emission standards under the Federal Clean Air Act, leading to cleaner and more efficient wood-burning appliances.

The science of wood combustion

Wood is a complex and versatile fuel, and a deep comprehension of its combustion is crucial for both professionals in the field and homeowners trying to keep their wood-burner in tip top condition. This understanding underpins various judgments and practices regarding the maintenance and operation of fireplaces and stoves. For instance, the design of efficient wood stoves that require strong draft is informed by the recognition of the ignition temperatures of gases released during wood combustion. Similarly, understanding and addressing issues like excessive creosote formation or difficulties in starting a fire often relies on the fundamentals of combustion.

Combustion of solid fuel occurs in both open fireplaces and enclosed woodstoves, but the topic of efficiency is more pertinent to woodstoves, as fireplaces are generally not evaluated primarily on this aspect.

Setting the stage (fireplace?)

Although the technical details of wood burning might not captivate everyone, anyone involved in the heating industry or interested in appliance operation and venting systems (that includes homeowners who want to take the best care of their hearth properly) should grasp the intricacies of combustion.

Combustion requirements:

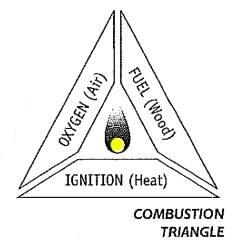

Combustion requires three elements: air, fuel, and heat. In any functioning solid fuel appliance, the hydrogen and carbon from the fuel combine with the air’s oxygen, converting the fuel into heat, chemicals, and gases. The absence of any of these elements halts combustion. If the balance is right, the process becomes self-sustaining. See the illustrated ‘Combustion Triangle’ below.

Complete combustion generates water vapor, carbon dioxide, and heat, leaving behind non-combustible ashes. In contrast, incomplete combustion results in carbon monoxide, hydrocarbons, and other gases, alongside water and ashes. The combustion rate of solid fuel is largely dictated by air availability, making the air-to-fuel ratio a key factor in optimal fuel burning. Appliances are designed with controls to adjust the air supply, and understanding these mechanisms is increasingly important due to advancements in technology.

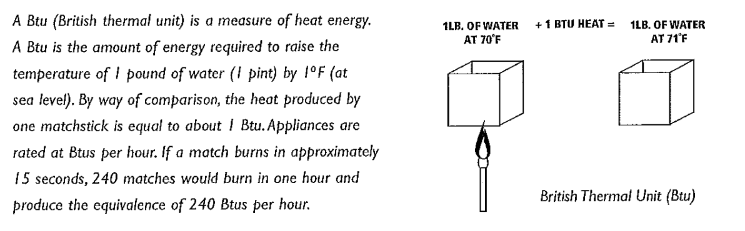

The energy content of fuels varies and is typically measured in British thermal units (Btu) per pound. Heating value, while related to energy content, is also influenced by factors like moisture content. As noted in the image below, a BTU is the amount of energy necessary for raising the temperature of one pound of water by 1 degree Fahrenheit at sea level, approximately the energy contained in one matchstick.

Stages of wood combustion

Wood combustion is a multifaceted process, involving a series of stages that occur both consecutively and simultaneously within the fire chamber. These stages are conceptual tools for understanding the process rather than precise descriptors of sequential reactions.

Stage I: Moisture Evaporation

Heating wood causes moisture to evaporate, absorbing heat and thereby delaying the progression to further combustion stages. High moisture levels demand significant energy to evaporate the water, impeding fire ignition and reducing the heat available for use.

Stage II: Vaporization of Hydrocarbon Compounds Rising temperatures lead to the breakdown of wood’s chemical structure and the vaporization of hydrocarbons through pyrolysis, yielding gases and tar droplets while leaving behind carbon-rich charcoal. At this point, these vapors are not yet combustible.

Stage III: Gas Vapor Ignition and Combustion If the vaporized gases reach their ignition temperatures in the presence of oxygen, they will ignite. Temperatures ranging from 540°F to 1,225°F are necessary for this stage, depending on the availability of oxygen and the specific gas. Efficient combustion requires that gases remain in the combustion chamber long enough to achieve these temperatures, which can be hindered by the moisture content of the wood.

Stage IV: Char Burning Finally, charred wood will only burn when in direct contact with oxygen, and this occurs at temperatures above 950°F. Charcoal, being primarily carbon, burns at high temperatures and with minimal flame.

Practical Applications

Now that we understand the basic science behind wood combustion, and have discussed how energy is produced from wood, let’s talk about applying this theoretical knowledge to real-world situations.

Starting a Fire in a Solid Fuel Appliance: A comprehensive understanding of combustion principles is vital when starting a fire in a solid fuel appliance. For successful ignition, the air controls should be fully open to maximize airflow, with the woodstove door possibly ajar to allow additional air if necessary. The type and condition of the fuel are equally crucial. Kindling, ideally small and dry, should be ample to sustain the fire until larger logs can be added. Heat is the catalyst that begins the process, and maintaining high firebox temperatures during startup is critical. This includes avoiding actions that introduce too much cool air or prematurely starting appliance blowers, which can dampen the firebox temperature.

Impact of Leaving the Woodstove Door Open: Leaving the woodstove door open during ignition may seem beneficial, but it actually lowers the firebox and chimney temperatures due to the influx of cooler air. A slightly ajar door, however, increases air velocity and turbulence, enhancing ignition and combustion.

Troubleshooting Fire Starting Issues: Troubleshooting fire starting problems in a solid fuel appliance can be methodical, akin to addressing small engine issues. Check for proper air flow, such as an open damper or glass doors, and the effect of room air circulation. Assess the fuel, considering the type and dryness of kindling and the timing and quality of fuel additions. Evaluate the heat generation, observing whether the fire’s intensity is consistent or fluctuating, and whether blowers are used appropriately. Monitoring firebox temperatures with thermometers can provide valuable insights.

Smoke Emission Analysis: Visible smoke from a chimney indicates incomplete combustion. Smoke signals that moisture evaporation or pyrolysis stages are active, with unburned materials being emitted. This could be a temporary phase during startup or refueling, but persistent smoke suggests issues like inadequate appliance design, malfunctioning components, or improper operation leading to insufficient combustion temperatures and air supply.

Summary

By applying the theoretical concepts of wood combustion to practical scenarios, individuals can enhance their understanding and mastery of wood-burning appliances. Not only does this knowledge contribute to more efficient and eco-friendly heating practices, but it also empowers users to diagnose and resolve common operational issues! These principles, while technical, have tangible benefits that can lead to improved appliance performance, reduced emissions, and a better understanding of the nuanced art of wood burning.