Cautionary Note: It’s imperative to acknowledge the inherent risks involved in servicing gas fireplaces and stoves, which can result in explosions or gas leaks. We strongly advise employing a proficient technician possessing the requisite knowledge and tools for safe troubleshooting and installation of any replacement components. The information provided here is not exhaustive and any attempt to troubleshoot or replace components is at your discretion and risk.

Standing pilot stoves or fireplaces incorporate a thermocouple and/or thermopile to monitor temperature and manage the operation of the fireplace. By pressing and holding a piezo igniter button situated on or near the valve, a pilot flame is generated, remaining ignited while the fireplace is operating (hence the name ‘standing’ pilot). The system’s popularity stems from its non-reliance on electricity, ensuring a constant heat source even during power outages in harsh weather conditions.

Understanding Thermocouples:

Thermocouples consist of an insulated copper tubing housing two dissimilar metallic wires connected at both ends. When the tapered end of the thermocouple detects heat from the pilot flame, the heat traverses down the two different wires, forming a low-voltage electric current upon reconnection. Measured in millivolts, this electric signal instructs the gas valve to release gas to sustain the pilot flame.

In stoves and fireplaces, thermocouples are integral for temperature detection and ensuring the pilot light stays ignited. If the pilot light extinguishes, the thermocouple will halt the gas flow from the valve as a safety mechanism.

Demystifying Thermopiles:

A thermopile resembles a stout, circular probe. Inside this thicker probe, multiple smaller thermocouples work together. These thermocouples synergize to produce a more potent electric current, with thermopiles boasting enhanced temperature sensing accuracy due to their heightened thermal sensitivity compared to a single thermocouple.

Utilized in gas stoves and fireplaces, thermopiles generate a low electric voltage to open the gas valve, allowing gas to enter the burner. They generate sufficient power for temperature regulation via a thermostat like a remote or wall thermostat.

Preparing for testing

Essential Tools:

- Multimeter

- Extra-fine grit sandpaper and/or steel wool

- Jumper wire equipped with spade clips

Common Problems: The most common issue experienced with a gas fireplace or stove is difficulty turning it on, and or keeping it on. If you are capable and careful, some basic troubleshooting can help identify the problem before opting for professional assistance. It’s pivotal to remember the danger associated with incorrectly serviced gas appliances and to resort to expert help for any tasks beyond your capacity.

Pilot Light Issues:

The absence of a pilot light halts the entire fireplace operation. Occasionally, the pilot might have been extinguished and reigniting it as per the manufacturer’s guidelines could solve the issue. Ensure to refer to your fireplace’s user manual for model-specific instructions. (Note that if this occurs regularly, there is likely a faulty part or drafting/venting issue going on as well)

Verify your fuel supply levels if it is a propane unit. A lack of fuel will prevent the fireplace from lighting up. If this is a natural gas fireplace, Ensure the manual gas valve is open. After verifying the fuel supply, there are a few more troubleshooting items to help you narrow down the issue:

- Is the pilot sparking? Pressing and holding the piezo igniter button should generate a “click” sound as a spark is sent to the igniter electrode. If no spark is observed, ensure a secure connection of the electrode wire to the piezo, check for any pinched or broken igniter wire, and inspect the porcelain base of the electrode for any damages. If everything appears fine, replacing the piezo igniter might be necessary.

- Is the pilot lighting? A visible spark but no pilot lighting often indicates a gas flow issue. If gas is smelled in the firebox, check the pilot orifice and pilot tube for any obstructions hindering gas flow from the control valve to the pilot hood.

If these inspections don’t rectify the issue, it’s wise to consult a technician capable of checking for air in the gas lines and validating the proper gas inlet supply. Equipped with special gauges, a qualified technician can measure gas flow pressure and ascertain if a gas valve replacement is required.

- Is the pilot extinguishing? If the pilot ignites but immediately goes out, a malfunctioning thermocouple is likely the culprit. Attempt re-igniting the pilot. If it fails to stay lit, cleaning and testing the thermocouple is advisable.

Thermocouple Test

- Start by terminating the gas flow at both the gas valve knob and the manual shutoff valve.

Inspect the thermocouple tip within the pilot assembly for carbon accumulation. Cleaning the tip with extra-fine steel wool and/or fine grit sandpaper can help. - Set your multimeter to the millivoltage measurement mode. Connect one multimeter lead to the thermocouple’s copper tube and the other to the end of the thermocouple where it attaches to the gas valve.

- Using a lighter or a small butane torch, heat the thermocouple tip for around 30 seconds. The multimeter should display a reading between 25-30 millivolts.

- A reading below 25 millivolts warrants a thermocouple replacement. If these measures don’t solve the problem, seeking expert assistance is highly recommended.

Investigating a Malfunctioning Burner:

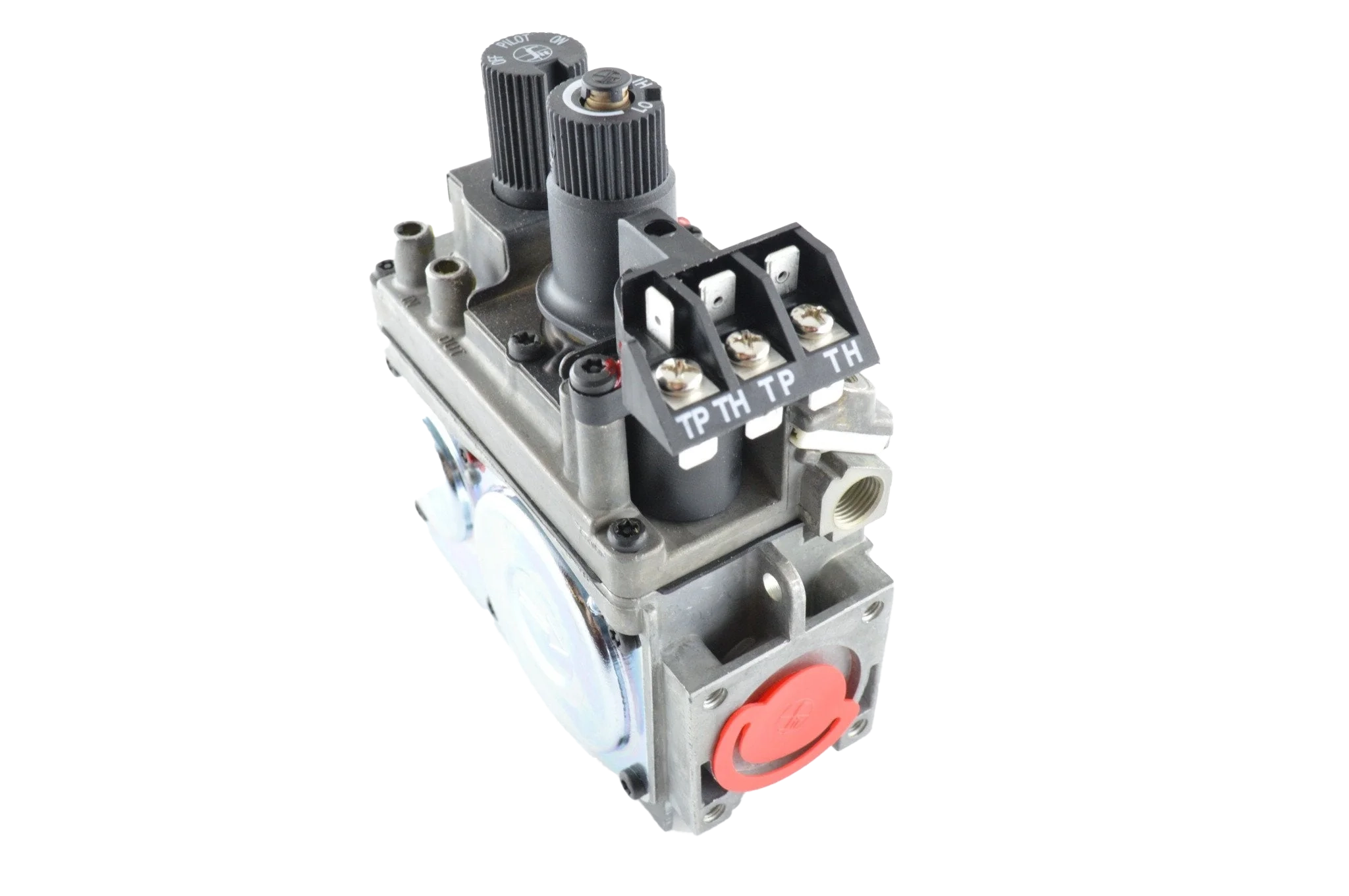

If the pilot remains lit but the fireplace burner still isn’t coming on, the burner and gas valve are your next focus points. A standing pilot gas valve, also known as a millivolt gas valve, possesses three electrical contacts labeled TH, TP, and TH/TP.

- TH means thermostat (like a thermostat, remote, or switch)

- TP means thermopile (the thicker probe in the pilot assembly)

- TH/TP connects to both thermostat and thermopile.

Burner not lighting?

- Thermostat: Begin by examining the thermostat if the burner fails to ignite. This could be in the form of a wall switch, a wall thermostat, or remote. Confirm if the thermostat is correctly set to call for heat (i.e. that you don’t have it set for 68 degrees and it’s 68 already) and inspect the wiring for any loose or broken connections, especially the terminals on the valve.

- Thermopile: The thermopile harnesses the pilot flame’s heat to generate a millivolt signal directing the gas valve to release gas to the burner. The thermopile ends should connect to the TP and TH/TP terminals on the valve. Manually inspect the thermopile probe in the pilot assembly for carbon buildup. Cleaning the thermopile with extra fine steel wool and/or fine grit sandpaper may help. A multimeter can also be used to test the thermopile, though the process is different than the thermocouple test.

Thermopile Test:

- Ensure the pilot light has been burning for 2-4 minutes and that the wall switch /thermostat is off.

- Make sure your multimeter is set to measure millivoltage.

- Connect the multimeter leads to the ends of the two thermopile wires where they attach to the valve.

- The multimeter should register a reading between 300 -750 millivolts. A reading below 300 millivolts indicates a thermopile replacement is needed.

Valve Operator Heads:

- If the thermopile generates the correct voltage, test the valve terminals with the multimeter.

Valve Test:

- Ensure the pilot light has been burning for 2-4 minutes.

- Set your jumper wire between the “TH/TP” and “TH” terminals of the valve operator head.

- Make sure your multimeter is set to measure direct current this time, not millivolts.

- Connect leads to the “TH/TP” and “TP” terminals of the valve head.

- A reading of 225 millivolts or above is expected. If the reading is below 225, the gas control valve requires replacement.

Thermostat Testing

If the fireplace still malfunctions, testing the thermostat circuit for continuity should be your next step.

Continuity Test

- Disconnect the thermostat circuit wires from the TH/TP and TH terminals and attach the multimeter leads to each wire.

- Make sure your multimer is set to measure ohms (resistance) this time. (Ω).

- Turn the rocker switch to the ON position to ensure the thermostat contacts are closed, completing the circuit. If the multimeter displays no resistance, there’s no continuity, indicating the thermostat wires or switch needs replacement.

Assessing Burner Flame Quality:

If the flame appears too low or too high, double check that the regulator on the gas control valve and the burner orifice(s) are the recommended parts for the gas type used by your fireplace. Natural gas and liquid propane call for different air to fuel ratios, hence, using the correct regulator and orifices is crucial. If issues persist, a local technician with the right tools and expertise to test the incoming and outgoing gas pressure should be consulted. A competent technician will also inspect the burner tube for blockages, conducting detailed diagnostics to determine if the valve or burner requires replacement, using specialized tools.

Miscellaneous Concerns

- Unusual Odors: Odd smells might suggest that it’s time to clean the fireplace and/or chimney pipe. Consult your owner’s manual for the recommended cleaning and maintenance schedule. During cleaning, exercise caution to avoid damaging the delicate logs. Any excessive accumulation of dust, dirt, or soot should be managed by an expert. If gas or melting wires’ smell is detected, cease using the fireplace immediately and wait for a trained professional to examine it in detail.

- Unfamiliar Noises: While some sounds might be typical for your stove or fireplace, any new sounds accompanying operational issues shouldn’t be overlooked. A poorly adjusted pilot flame or dirty burners might produce a low, rumbling sound. Certain units come with an optional convection blower to enhance heat distribution in the room. Over time, convection blowers might develop a high-pitched squealing sound, indicating worn-out bearings, and signaling that the blower needs replacement.

- Excessive Soot: If the oxygen ratio in the fireplace is either too high or too low during operation, it might result in excessive creosote accumulation. This might imply that the air setting needs adjustment or there might be an obstruction like leaves or a bird’s nest blocking the flue pipe. In such scenarios, engaging a qualified technician to inspect and clean the fireplace is advisable as they possess the necessary tools to adjust air settings and identify potential hazards.

Final Thoughts

Maintaining Your Gas Fireplace

- It’s recommended to have your gas fireplace professionally cleaned and inspected annually. This generally includes cleaning the burners and pilot assembly, examining safety systems, testing the ignition system, and inspecting the flue for blockage or leaks. Adhering to the suggested maintenance schedule ensures a safe and dependable fireplace operation throughout the heating season.